Vacuum packing machines with one or more chambers for vacuum packing in line with our flowpack machine. Perfect for vacuum-pack cheese, pizza, meat and fish, using barrier film that maintains the hermetic seal. Without using pre-formed bags, our solution allows creation of a bag starting with the reel “to measure” with enormous savings in material. What is development, if not an optimal result for minimum consumption? The world is always moving forward and our technology is ahead of it.

General features

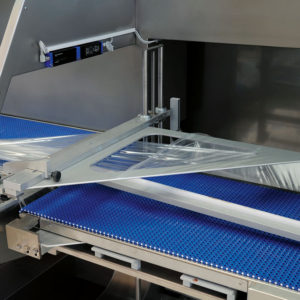

The huge versatility of the machine allows the packaging of the various types and dimensions of products with automatic vacuum packing line starting from the reel.

The solution for vacuum packaging various types of food products.

Automatic vacuum packing machine working with film roll, flat or center-folded. This major innovation means pre-formed bags are NOT necessary, saving 40% on film costs. The only automatic machine in line available that works with a film roll to create vacuum packing. More versatility and huge savings. Multi-format machine WITHOUT rigid forming machine and no pre-formed bags.

Specific features

Canter level structure: allows easy cleaning and access to the machine. Particularly suitable for the food sector. It can be combined with a canter level shrink tunnel with opening chamber and additional canter level conveyor belt. Vacuum packing lines are also available painted, non-stainless steel, for non-food products.

The packaging machine can be sold separately and integrated with a vacuum packing chamber, or in line with the chamber manufactured by us.

Vacuum packing chamber sized to work with the products to be packed. Configurations available with 2/3/4 chambers.

Gas injection system. Modified atmosphere (MAP).

Film dispenser unit with triangle for flat film or center-folded from reel. Rapid and simple format change without pre-formed bags. Highly versatile, with savings in material costs.

Packaging machine and vacuum chamber connected using belts or diverters, based on the customer's requirements. Customized, tailor-made layout.

Intralox conveyors for food or smooth belts which are easily dismantled (based on the product) excellent for cleaning.

Different size chambers available, based on the product.

Packaging machine with side sealing to form the bag.

Possibility of vacuum packing various types of products, even non-food in automatic mode.