Highly automated cluster carton sleever for single products or multipacks with rotating motorized carton picking system.

Compact layout integrated with infeed conveyor, the motor driven infeed pusher and carton picker are precise and energy saving.

Partly automatic change over with motorized movements, by touch screen.

This machine is highly accessible and this facilitates the maintenance and cleaning operations.

General Features

HighLy automated carton sleever, engineered to wrap carton blanks around single products or multipacks.

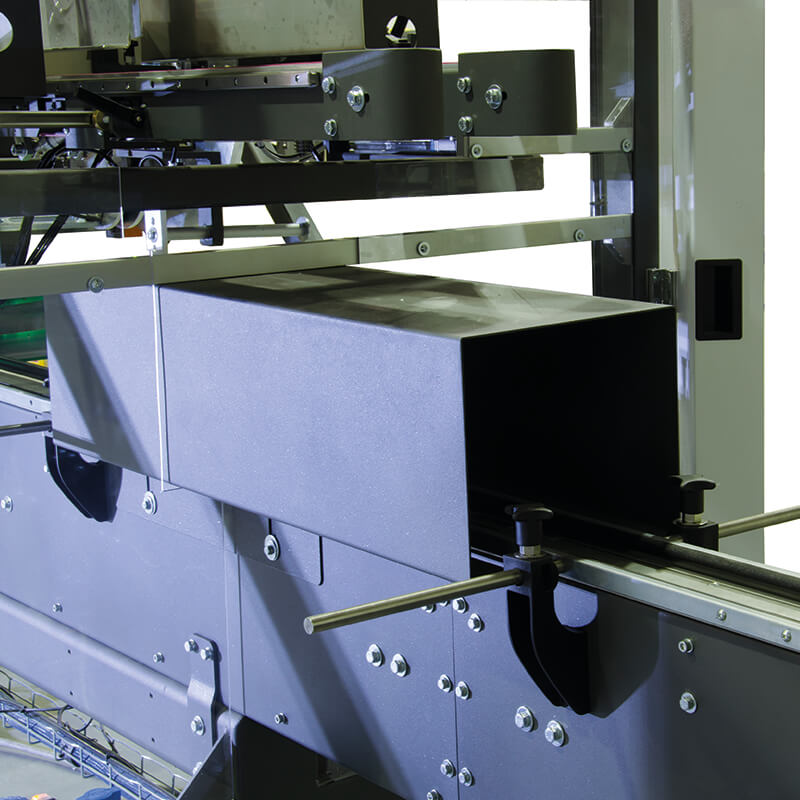

Carton blanks are picked from the carton sleeve magazine and are placed above the product/multipack and folded around it.

A hot melt point completes the cycle by gluing together the flaps underneath.

The loading of the product onto the machine is done by phasing and accelerating infeed conveyors which ensure a reliable loading timing for maximum efficiency and minimum waste.

Mostly automatic change over with motorized movements, by touch screen.

This machine is highly accessible and this facilitates the maintenance and cleaning operations.

Specific Features

Reduced space required for a high performance machine.

ICE carton sleever machine’s standard carton sizes vary from a minimum of 60 x 60 mm to a maximum of 300 x 495 mm, with products dimensions varying from min 60 x 40 x 20 mm to max 270 x 270 x 130 mm. Different formats are available depending on feasibility.

Standard: painted steel, with galvanized chains, pulley and pinions. Available in completely INOX version, with nickel-plated chains, pulley and pinions.

Phasing and accelerating infeed conveyor, with reliable infeed timing mechanism that provides maximum efficiency with minimum waste.

Side motorized guides or top forming shape conveyor for tight and precise carton sleeve around the product, for a neat final look.

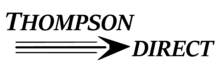

Carton loading is mounted on sliding linear guides for a further accessibility during the maintienance operations. Wide carton blanks magazine for different sizes, quick and easy change of format.

Quick and easy manual adjustable width on belt by one notch at a time, depending on product's size.

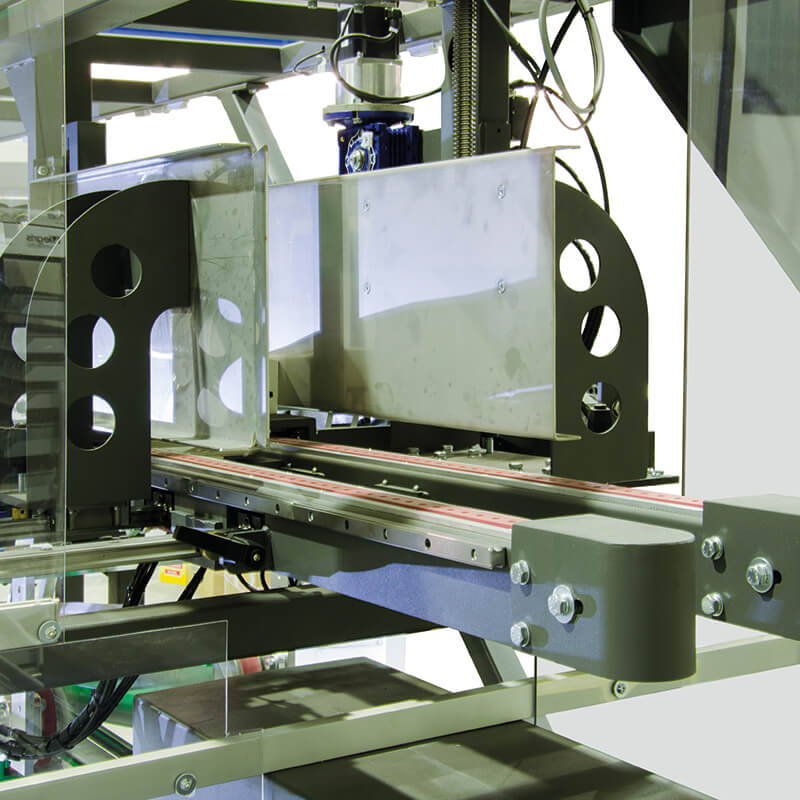

Extremely reliable continuous motion and precise rotary arm collects the carton through suction cups and places it above the incoming product.

User friendly OMRON touch screen, with recordable programs menu system recipe based. Most of format changes and movements are electric and can be recorded and recalled. Machine can be operated from both sides, left and right machine with sliding or bifolding doors.