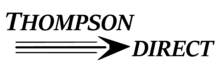

Automatic cartoning machine with filling from the side for use with American boxes or pre-formed boxes.

Automatic opening, filing and closure of the box.

The box is opened by gripping the box using the double set of suction cups on both sides of the box.

Reduced dimensions, high speed, versatile format change.

For insertion of products in boxes of various nature: blisters, thermoformed trays, rolls of paper, boxes of food, tissues, napkins, cups, bags of food with a square or pillow base.

The loading system varies based on the type of product.

General Features

The horizontal cartoning machine for American boxes was designed to be placed downstream of the packaging lines: to join a group of products coming from a packaging machine, positioning them at multiple heights with the front and depth of the rows settable.The package produced, formed by the loader with the stacker unit, is subsequently pushed and inserted inside a box formed by the machine.The filled box is pushed towards the output and the machine closes all the flaps and "tapes" it on two sides.

Optional: glue closure using the Hot Melt gluing system.

Specific Features

The strengths of the cartoning machine are:• compactness, reduced size, high speed up to 10 boxes/minute standard or up to 20 boxes per minute with a double box opener.

• automated adjustments.

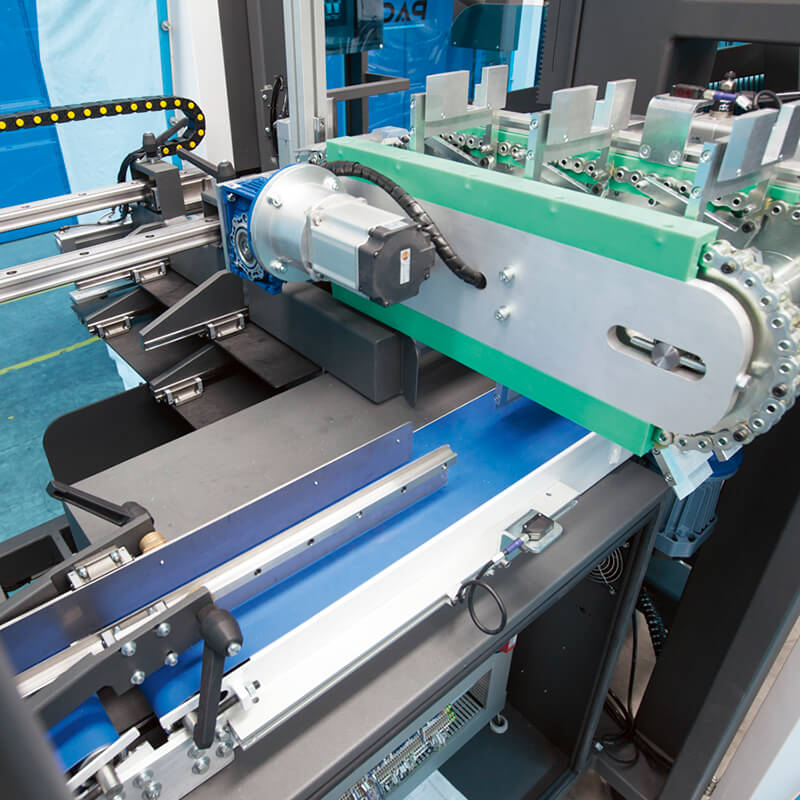

• fast format change, easy access to the parts to adjust, movements on the dovetail guides and recirculating ball slides.

• Siemens management PLC

• Versatile format change and easy access to the parts to adjust, movement of the actuators on liner guides.

Positive box opening in automatic mode and insertion of the group of products in it.

New ergonomic design. All the parts of the machine are easility accessible thanks to the innovative, side-opening doors. The collection module can be easily separated from the boxing maching for format change.

Feeder belt with various types of automatic loading, based on the product.

Double operator position thanks to rotating touch screen.

Automatic box opening system.

Automatic box closure with adhesive tape or hot glue. Automated side guides. Automatic adjustment.

Machine managed by Siemens PLC and intuitive touch screen. Auto-adjusting format change.

Canter level structure for perfect maintenance and cleaning.