Mailvision is a camera system and software platform that allows the design of flexible and versatile solutions to supervise and control the processing of high-volume document and mail-kit production. It is capable of reading text, barcodes, address blocks, number sequences and so much more - Mailvision takes the physical data it reads and converts it into something readable by the computer. Once the data is read by Mailvision, it can communicate with other programs on your system - such as Composer - and can decide what to do with that data. Some examples include verifying a customer's address block, deciding what pieces to insert into an envelope, and printing a variable image based on matching information gathered by Mailvision to data forms in another program.

The Mailvision solutions:

· Eliminate a significant portion of the labor associated with quality control for complex, high-value applications

· Inspect each and every document that passes under its reading device

· In the event of an error, diverts the error pieces or stops production automatically, sounds an alert and displays an error indication on its screen interface

· Massively increase the integrity of document output, and substantially reduce the cost of achieving this level of integrity

· Log all activity in detailed, customizable data table architectures for end-to-end validated mail-kit and document production

Applications

· Matching of multiple documents

· Component selective inserting

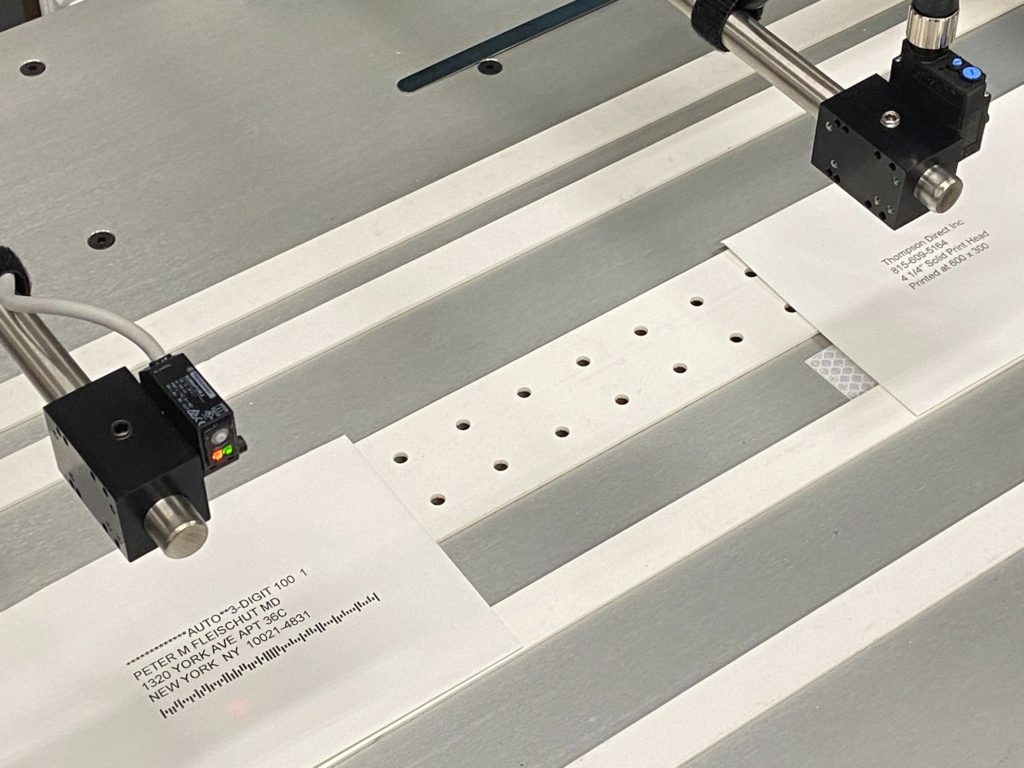

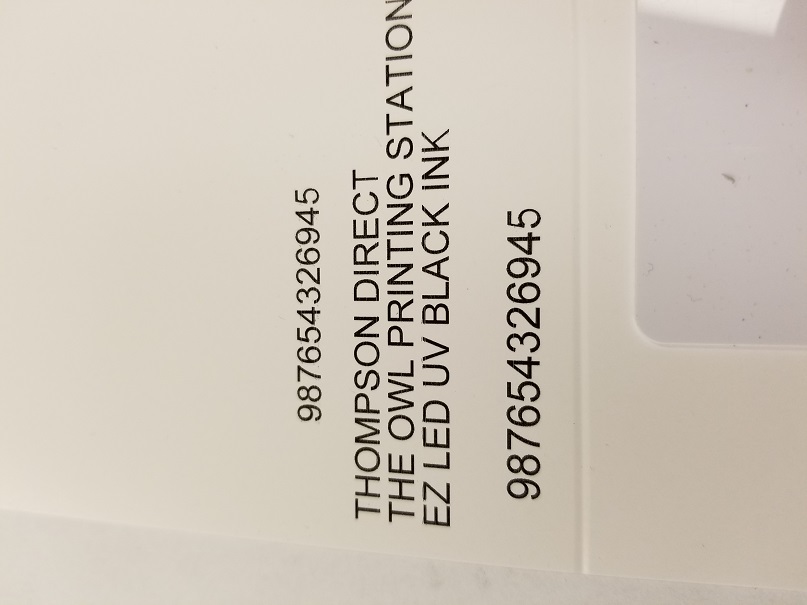

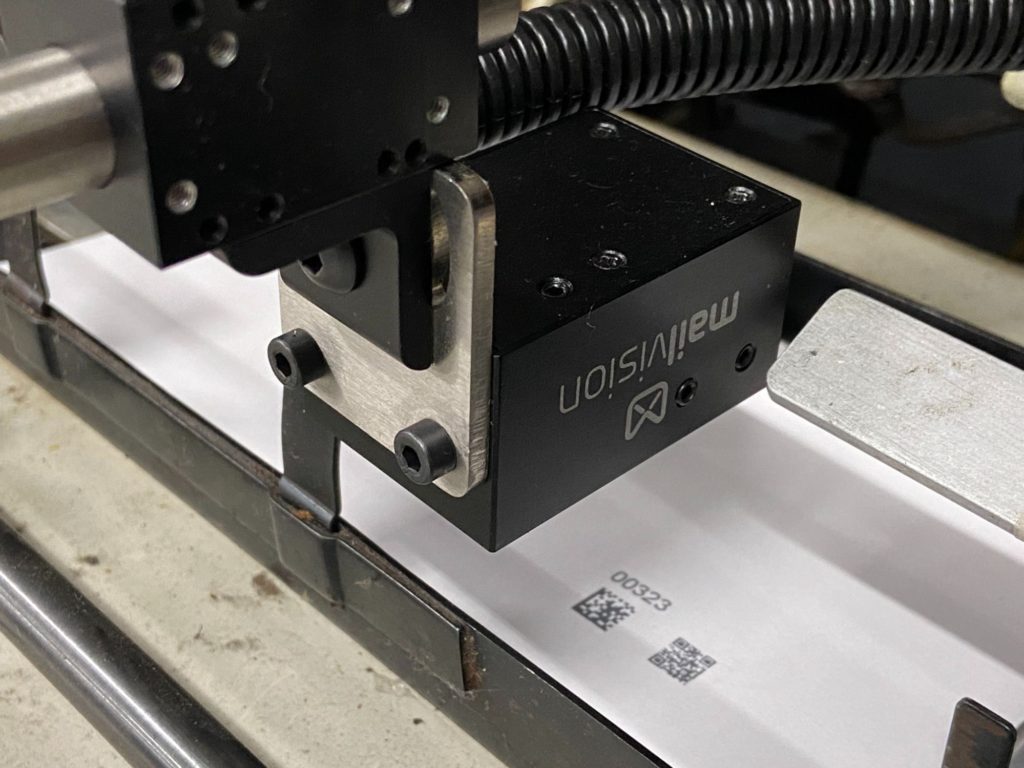

· Read and print: in-line inkjet addressing/1:1 messaging

· Base stock validation

· Address Block validation

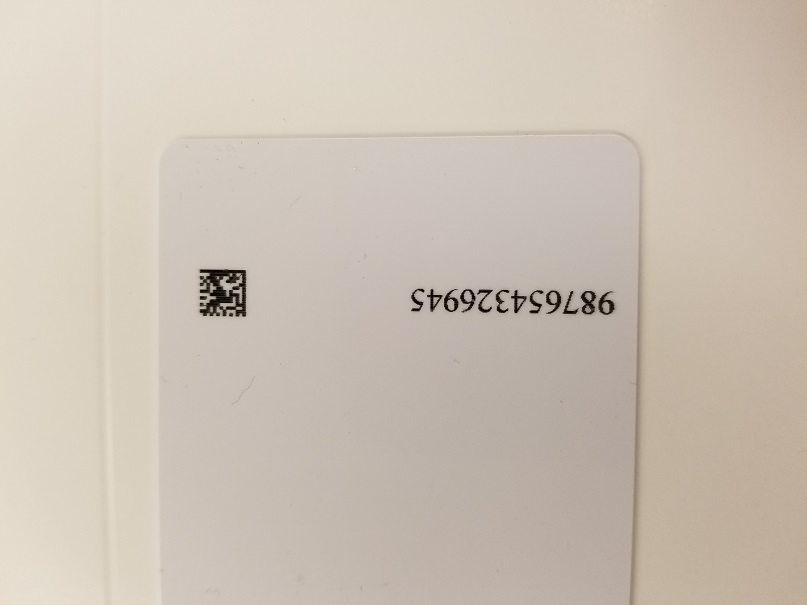

· Numeric, and alphanumeric, sequence verifications

· Component grouping

· Combination of any of the above-mentioned functionalities

Benefits – “Productivity & Costs”

· Eliminates high-cost sampling, fanning and related labor-intensive manual quality control procedures.

· Reduces down-time caused by manual quality control methods and increases the capacity of production mail and document processing equipment.

· Reduces spoilage and re-work.

· Offers an easy-to-use interface for set-up mechanics and operators.

· Identifies document errors in real-time and enables validated variable print document processing at top throughput.

· Enables management by measurement; by gathering data on every document and mail-kit processed, Mailvision “sees” production output from each unit of host equipment Mailvision integrates with and each operator Mailvision interfaces with.

Benefits – “Customers & New Business”

· Improves key account penetration by enabling new validated variable document production applications.

· Expands service levels by increasing the capacity of production equipment and the quality of document output.

· Raises service levels by providing comprehensive, feature-rich reporting functionality.

· Increases the quality of document processing output by preventing against error documents and mail-kits from entering the output stream.

· Enables exceptionally flexible, validated variable document compositioning options.

· Provides flexible job processing options resulting in better use of document “real estate” and improved aesthetic presentment.

· Enhances corporate image through the use of state-of-the-art document processing technology.

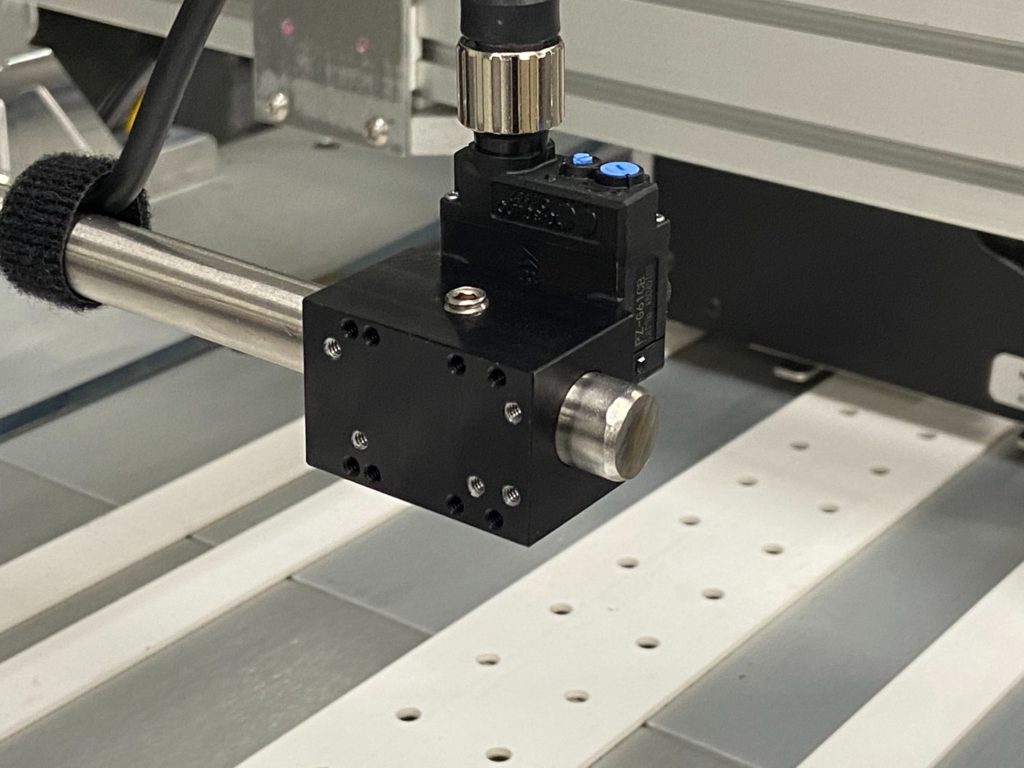

Mailvision is capable of reading:

· Alphanumeric characters (OCR) Most fonts

· Bi-dimensional barcodes (e.g, DataMatrix, PDF417)

· Linear barcodes (e.g., Code 39, Code 128, Interleave 2 of 5)

· Patterns & symbologies

· Custom codes

· Optical marks

· Magnetic stripes

· RFID

Just a few examples of what the camera can read!

Data Logging:

Either we create a log of what we read with a date time stamp, operator info and such or

Reprint files:

We could load a customers data file and check off what we read on the data file and create a reprint file.