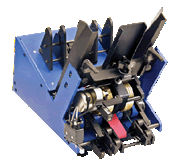

Add-A-Station (EX Series)

FEATURES

The EX Feeder comes standard with our Patented Dynamic Rotation Technology, heavy duty 1/4" thick powder coated side frames, ground fault, product guides and variable speed control.

ADVANTAGES TO INVESTING IN AN EX FEEDER

-

Adding stations to your existing inserter

-

Easy installation/space saver

-

Move from oen inserter to another

-

Miss (standard) and Double Detection (optional)

-

Higher throughput/lower cost

TECHNICAL SPECIFICATIONS

SE 900 EX / ECO 900 EX

- Maximum Product Size: 9.125" W x 5.5" L

- Maximum Product Size MM: 231.775mm W x 139.7mm L

- Minimum Product Size: 5" W x L - 2.5" - L

- Minimum Product Size MM: 127mm W x 63.5mm L

- Maximum Product Thickness: .125"

- Maximum Product Thickness MM: 3.175mm

- Minimum Product Thickness: .002"

- Minimum Product thickness: .0508mm

- Presentation Sensor: N/A

- Sleep Mode: Standard

- Double Detection: Only Available on the ECO 900 EX

- Select On Demand: Optional

- Feeder Capacity: 20" Vertical

- Batch Count: N/A

- Electrical: 120VAC / 240VAC

- Speed: Variable 20 to 350 Ft/Min.

- Drive Motor:Variable DC

APPLICATIONS

Add additional inserting stations to your gripper arm inserter.

OPTIONS

-

Batch Counting

-

Credit Card Guides

-

24 AC/DC Interface

-

Select on Demand

-

Double Detection (only available on ECO Model)

FEEDABLE MATERIALS

-

Letter

-

Half

-

Double Parallel

-

Engineering

-

Z

-

Gate