Star Evo SS

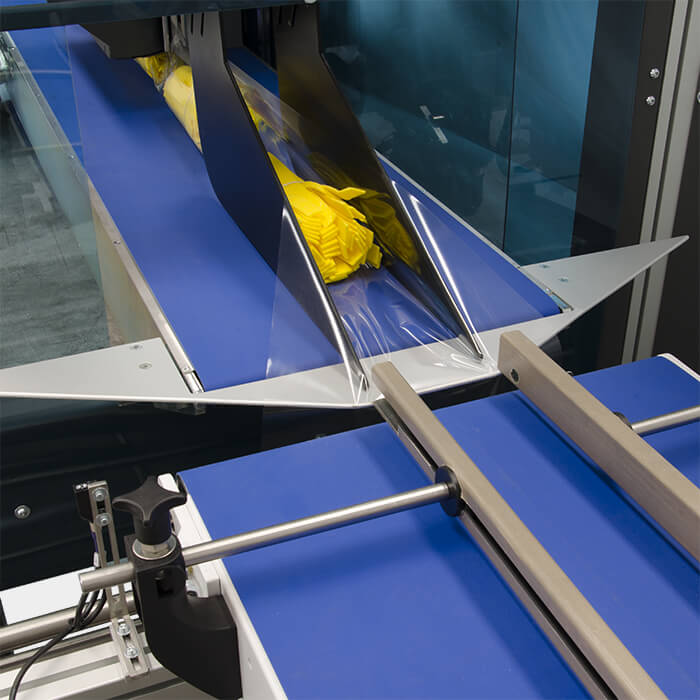

STAR EVO SS Top sealing flowpack

Top sealing flowpack machine which wraps film completely around the product. The two sides of the film are merged together and sealed above. The new generation designed machine is super-accessible and simple to use. Excellent for total packaging and closure of various types of products with flat sheet, heat shrinking film. A highly flexible machine, thanks to the possibility of having it in various sizes; with a fixed rotating, intermittent or box motion bar for simple sealing, wire or knurled and simple packaging or with Euroforo and/or easy opening. It aims to increasingly reduce film consumption and give aesthetically pleasant results. Excellent for food and other sectors.

General features

STAR EVO SS

Compact, simple and flexible flowpack machine to cover an increasingly vast range of packaged products: cosmetics, pharmaceuticals, plastic, food, electrical products, industrial and household products.

Suitable for manually or automatically loaded single or multipack products created with additional systems (stackers, multipack formers, diverters, etc.).

Huge savings in film and energy thanks to the possibility of producing perfectly tight packages around the product.

Extraordinarily accessible structure, allowing work from both sides, 3-position operator station thanks to the rotating touch screen.

Excellent design for maintenance and cleaning. Available in a painted and stainless steel version.

Specific features

STAR EVO SS is available in the 'BABY' version with bar width 300 mm; version 500, 600, up to the widest version, 800 mm, with standard height of 300 mm or with optional up to 450 mm.

A shrink tunnel from our range can be added to complete the packaging cycle.

Thanks to the optional and "double" sealing systems, you can work with all the types of film available on the market: polyolefin, polypropylene, flat or center-folded film, neutral or printed (with Euroforo, with a Handle, with Pre-cutting for easy opening and with "open-close").

Available in intermittent, box motion or rotary version, based on speed requirements.

COMPONENTS:

Motors: ABB

Reducers: MOTOVARIO

Bearings and Supports: SKF

Pneumatics' components: KUHKNE

PLC: SIEMENS

Electro-mechanic's components: MITSHUBISHI

Inverter: MITSUBISHI

Rele': OMRON