Automatic wrap around and multipack machine using pre-glued wrappers to form or flat blanks.

Highly automated multipack machine for single or multipack products.

The flat sheets of cardboard are picked from storage and are positioned over the tray or glass or other type of product to wrap with the cardboard blank and are then wrapped around the product.

Application of the glue point completes the cycle by joining the two box flaps.

The wrap around machine uses pre-formed wrappers picked from storage, opened and positioned on the belt in sections waiting for manual or automatic filling of the product arriving on the parallel belt.

General Features

Multipack machine (blank wrapping machine) with high automation for single packs or multipacks with a rotary automated servo-arm to pick the box: flat blank or case, in this case involving the automatic or semi-automatic horizontal wrap around machines. It works with pre-glued box and is filled on the side using manual loading by the operator or automatically using linear pushers or continuous rotation with parallel loading belts. Available also in a "vertical wrap around version" with 'tray display' and tray shape (single or multiple) with product filling from above and tray closure using hot glue.

PRODUCT DIMENSIONS: LENGTH 60-270 MM, WIDE 40-270 MM, HEIGHT 20-130 MM. Version available in STAINLESS STEEL.

Standard: Painted steel; chains, pulley, pinions are nickel-plated in the stainless steel version, in the standard version they are galvanised.

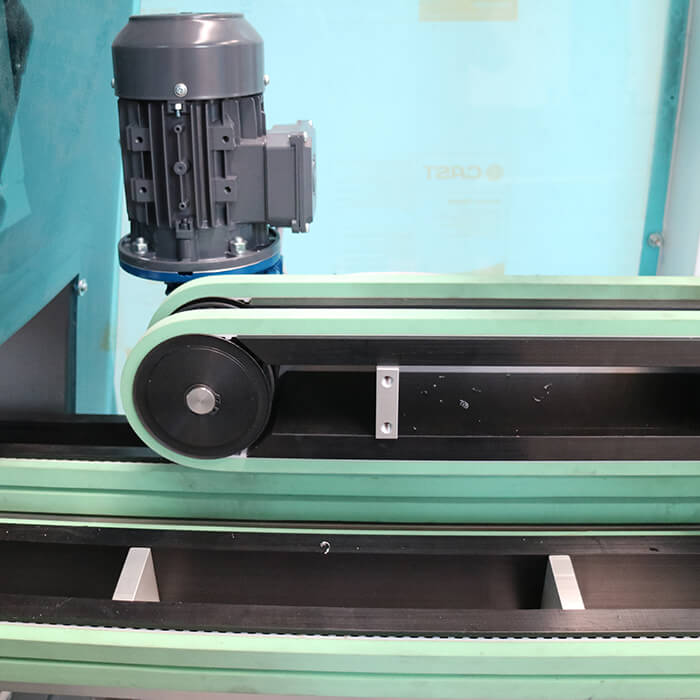

Output station with guide belts adjusted to the size of the dimensions of the box.

Mechanics in view, electric cabinet totally visible at eye level and easily opened.

SIEMENS or OMRON, intuitive touch screen.

Motorized side guides and upper belt in sections to guarantee stability of the product and positioning of the cardboard, even at high speeds.

Servo-automated box picking arm for maximum precision at high speed.

Phased belt with 'starwheel' spacing system.

Completely accessible canter level structure for easy and fast maintenance and cleaning under the machine, optimal sanitary-hygienic construction.

Lug conveyor with spaced palettes.