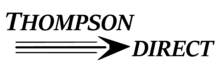

Bottom sealing flowpack machine whose film wraps completely around the product. The two sides of the film are merged and are sealed beneath, based on the application. New generation and design machine, super-accessible and simple to use. Excellent for total packaging and closure of various types of products with flat film, mostly polypropylene (also usable with POF). A highly flexible machine, thanks to the possibility of having it in various sizes; with a fixed rotating, intermittent or box motion bar for simple sealing, wire or knurled, or with Euroforo and/or easy opening. It aims toreduce film consumption and give aesthetically pleasant results. Excellent for food and other sectors.

General features

Compact, simple and flexible flowpack machine to cover an increasingly vast range of packaged products: cosmetics, pharmaceuticals, plastic, food, electrical products, industrial and household products.

Suitable for manually or automatically loaded single or multipack products created with additional systems (stackers, multipack formers, diverters, etc.). Huge savings in film and energy thanks to the possibility of producing perfectly tight packages around the product.

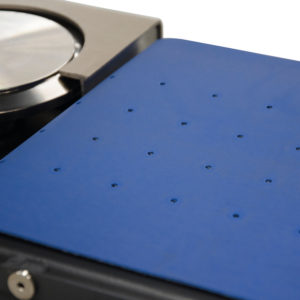

Extraordinarily accessible structure, allowing work from both sides, 3-position operator station thanks to the rotating touch screen.

Excellent design for maintenance and cleaning. Available in a painted and stainless steel version.

Specific features

Star Evo SI is available in the ‘BABY’ version with bar width 300 mm; version 500, 600, up to the widest version, 800 mm, with standard height of 200/300 mm or with optional up to 450 mm. A shrink tunnel from our range can be added to complete the packaging cycle. Thanks to the optional and “double” sealing systems, you can work with all the types of film available on the market: polyolefin, polypropylene, flat or centre-folded film, neutral or printed (with Euroforo, with a Handle, with Pre-cutting for easy opening and with “open-close”). Available in intermittent, box motion or rotary version, based on speed requirements.

Very versatile machine, with the possibility of equipping it also with a side sealing system in order to be able to use different films and obtain different kinds of packages with the same machine.

Motorized sealing bar with guesseting system.

Possibility of equipping the machine with a printing system for barcode or other information (continuous inkjet printing solution).

Optional of vacuum conveyors for light products stability.

Four pairs of wheels, for sealing and fin folding. Wheels diameter min. 120mm.

Hyper accessible structure; perfect for maintinence and cleaning. Front and rear or sliding opening doors.