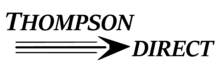

Continuous side sealing machine with intermittent, fixed bar (previous generation to the STAR EVO “new design”). we are more than sure about its reliability and that we are sure you’ll never get tired of using it. It can be used in all packaging sectors from industrial, to tissue, plastic, “household”, graphics industry, beverage, disposable products, wood and profile production industry, food and bottling.

General Features

Replaced in most sizes (500 - 600 - 800 by the renewed and redesigned version: STAR EVO) the SOL side sealing machine can work with all types of film (with optional sealing systems). The machine has 3 belts that allow considerable savings in film thanks to the reduced distance between the side sealer and the product. Saving 10 cm of film per pack. The cycle automatically stops when the product is used up. Our machines can all be combined with: infeed conveyor belts, with palettes, pushers, loaders (shutter and rotary), shrink tunnels, outfeed belts or stackers, manufactured by us.

Specific Features

The machine is equipped with a fixed transversal seal bar with intermittent operation which moves vertically as the product arrives, to cut and seal the front and back of the bag. Side sealing always takes place continuously to allow product packaging without length limits. Product width up to 1000 mm, product height up to 400 mm. Speed with A4 format up to 3000-4500 pcs/h. Packaging completely closed and sealed on 3 sides, with handle, with Euroforo and easy opening, in modified atmosphere (MAP): possibility of packaging in protected atmosphere with Polypropylene barrier film or coupled.

3-belt side sealing machine, giving flexibility and energy savings.

Film dispenser unit.

Reduced distance between the side sealer and the product, saving 10cm of film per pack.

Saving space, the machine can be placed against the wall.

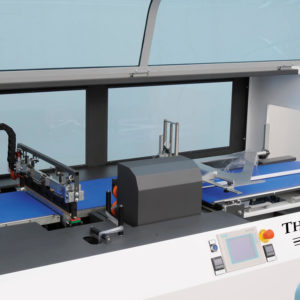

Easy format changes; motorized center sealer and triangle. Height up to 400mm.

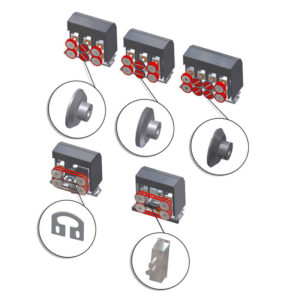

Flexibility: side & transversal sealing systems optional for all film types.

Film dispenser unit and waste collection unit, both placed in the front with a sliding door that is easy to reach. Removable film dispenser unit.

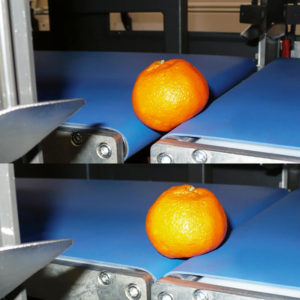

Belts can be placed alongside one another, offering standard flexibility of the product's range. Also enables work with very small/round products.