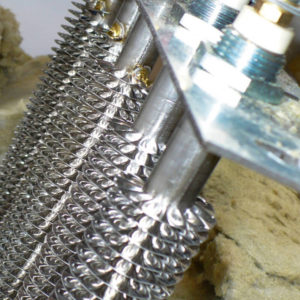

Hot air shrink tunnel. Attractive line, compact and accessible, functional and energy saving. The shrinking chambers retract the plastic film around the product, adapting the film to the shapes and dimensions of the product. New technical solutions reduce consumption to the minimum, thanks to excellent use of the ventilation and hot air recirculation system and production, on our packaging and flowpack machines, with increasingly tight packaging, sticking to the product.

General features

Complete recycling of hot air shrinking chamber. Adjustable air flow and speed. Digital temperature control. Automatic switch off when the temperature goes below 80 degrees. Transport on rotating or fixed silicone-covered rollers based on the film and the product you are working on. Thermal protector against sudden changes in current. It can be used with all shrinking films, PE with the addition of P.T.F.E-covered belt. For high speeds or very long products, there are versions available with additional chambers.

Specific features

The shrink tunnels were designed to solve shrinking problems of various sized products, up to 3000 mm, 600 mm high and can be used with all the shrinking films available on the market. They can support all packaging, flowpack and wrapper bundler machines, maintaining the same shape or being incorporated to the packaging machines, guaranteeing an elegant, ordered and compact line.

Easy replacement of the heaters, excellect accessibility to the chamber.

Optional available, straightener for multipack alignment.

Standard shrinking system with heaters or special with Leister. Perfect for printed film. Avoids deformation of film printing.

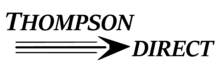

Conveyor belt with P.T.F.E. metal mesh or rollers, according to the size of the tunnel and the type of film.

The shrinking chamber of the tunnels can move horizontally thanks to the front handles to centre the products and arriving from the packaging machine and always obtain the best shrinking without any need to move the tunnel. Optional no longer necessary in the "EVO" version where the product always runs in the centre.

Intuitive control pannel with simple temperature speed adjustments and air flow or available in versions with touch screen adjustments.

P.T.F.E.-covered rollers that also rotate on themselves, avoiding leaving marks on the bottom of the pack.

Air flow adjustment with inverter, independent (one per chamber).

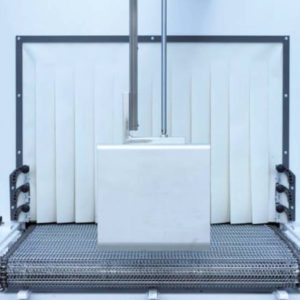

Flaps that open and adjust for improved ventilation and, as a result, better shrinking, adjustable from outside.