|

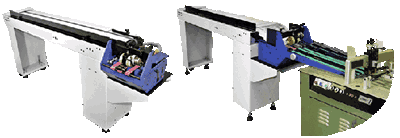

FEATURES OF A FEEDMAX

The FeedMAX is perfect for feeding magazines, self-mailers, postcards, and other types of products. The FeedMAX Series has all the characteristics of a high end Sure-Feed feeder which includes: Patented Dynamic Rotation Technology, "The Shaker" plate, heavy duty 1/4" thick powder coated side frames, product guides, remote stop, external run interface and variable speed control. The adjustable autoloader portion of the FeedMAX comes standard with the 6' autoloader (9' optional), product guides, variable speed and casters and an independent power switch.

ADVANTAGES TO INVESTING IN A FEEDMAX

- 3-4 months return on investment

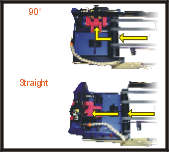

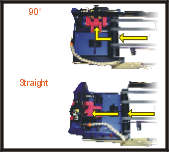

- Straight away & right angle capabilities

- High Capacity Adjustable Autoloader

- Improve product handling

- Feeds a wide range of products

- Reduce labor cost within the Work Cell

- Integrates easily with In-Line Vacuum Bases

TECHNICAL SPECIFICATIONS

- Maximum Product Size - 12"W x 13"L

- Minimum Product Size - 3.25"W x 5"L

- Maximum Product Thickness - .625"

- Minimum Product Thickness - .004"

- Feeder Capacity - 2000 #10 Envelopes

- Maximum Foot Print - H - 40" W - 16" L - 120" (9')

- Minimum Foot Print - H - 35" W - 16" L - 85" (6')

- Speed - Variable up to 500 ft/min

- Electrical - 120 VAC/240 VAC

- Separator - Dynamic Rotation Technology

- Drive Motor - Variable DC

APPLICATIONS

Interfaces with all ink jet bases and other continuous feed applications.

OPTIONS

-

-

-

Straight away & right angle capabilities

FEEDABLE MATERIALS

Envelopes 8 to 64 Page Sigs

Flats Pamphlets

Self Mailers Leaflets

Postcards Maps

Single Sheets Chipboard

Magazines Cardboard

Booklets Plastics

Folders Flyers

FEATURES OF A FEEDMAX-S

Shuttle Feeders limit your range of feedable products and stack heights. The FeedMAX-S is designed to eliminate both issues by shingling material on a high capacity conveyor that waterfalls into the feeder hopper. Combine the jogging wegde with Dynamic Rotation Technology will increase your productivity by three times. The FeedMAX-S comes standard with Sure-Feed's Patented Dynamic Rotation Technology, "The Shaker" plate, 6' autoloader (9' optional), External Run Interface, and Casters.

ADVANTAGES TO INVESTING IN A FEEDMAX-S

- 3-4 months return on investment

- Straight away & right angle capabilities

- Increase production on Shuttle Bases

- Improve product handling

- Feeds a wide range of products

- Reduce labor cost

- Integrates with any Continuous Applications

TECHNICAL SPECIFICATIONS

- Maximum Product Size - 14.5"W x 13"L

- Minimum Product Size - 3.25"W x 5"L

- Maximum Product Thickness - .625"

- Minimum Product Thickness - .004"

- Feeder Capacity - 2000 #10 Envelopes

- Maximum Foot Print - H - 43" W - 16" L - 120" (9')

- Minimum Foot Print - H - 38" W - 16" L - 85" (6')

- Speed - Variable up to 500 ft/min

- Electrical - 120 VAC/240 VAC

- Separator - Dynamic Rotation Technology

- Drvie Motor - Variable DC

APPLICATIONS

Ink jet, Tabbing, Labeling, Scanning and Folding.

OPTIONS

-

-

-

Straight away & right angle capabilities

FEEDABLE MATERIALS

Envelopes 8 to 64 Page Sigs

Flats Pamphlets

Self Mailers Leaflets

Postcards Maps

Single Sheets Chipboard

Magazines Cardboard

Booklets Plastics

Folders Flyers

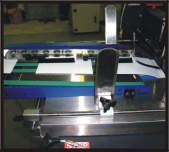

KEY FEATURES

Adjustable pile height using a

moveable photoeye.

Adjustable conveyor for different

size product.

"The Shaker" keeps the product

square and helps increase

separation.

Straight and 90 degree

configurations.

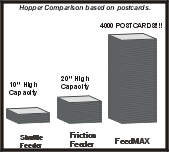

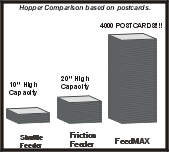

FeedMAX's product capacity is

approximately 5-6 TIMES that

of a Shuttle Feeder Hopper and

3-4 TIMES that of a Friction

Feeder Hopper.

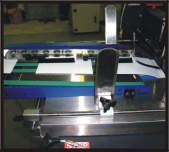

FeedMAX Series easily integrates

into any continuous feed application

such as an Ink Jet Base, maximizing

your production. |

| |