|

|

AUTOMATIC PRODUCT LOADER (APL)

An Automatic Product Loader (APL) is used to decrease the labor cost involved with repeatedly filling the friction feeder product-holding magazine. During high-speed feeding, an APL can be a great cost/time saver. The APL uses a horizontal conveyor system to support the products being handled and to gently fill the friction feeder as needed. The communication between the APL and the friction feeder's computer ensure that the transfer occurs smoothly and that the operator is alerted when the APL is running low on products. The alert is a blinking yellow light on the friction feeder, which gives the operator time to add products so that production levels are maintained. An Automatic Product Loader (APL) is used to decrease the labor cost involved with repeatedly filling the friction feeder product-holding magazine. During high-speed feeding, an APL can be a great cost/time saver. The APL uses a horizontal conveyor system to support the products being handled and to gently fill the friction feeder as needed. The communication between the APL and the friction feeder's computer ensure that the transfer occurs smoothly and that the operator is alerted when the APL is running low on products. The alert is a blinking yellow light on the friction feeder, which gives the operator time to add products so that production levels are maintained.

The APL uses a horizontal conveyor system to support the products being handled and to gently fill the friction feeder as needed. A Sensor is mounted in the in-feed magazine of the feeder. Once the product level falls below a pre-set level, the sensor will signal the loader to replenish the feeder in-feed magazine. The APL uses a horizontal conveyor system to support the products being handled and to gently fill the friction feeder as needed. A Sensor is mounted in the in-feed magazine of the feeder. Once the product level falls below a pre-set level, the sensor will signal the loader to replenish the feeder in-feed magazine.

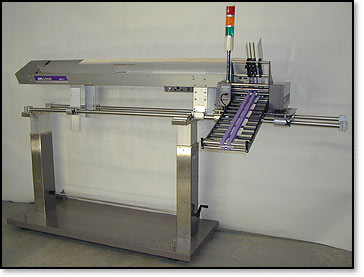

A reversed APL configuration.

The Automatic Product Loader can be positioned in a standard configuration in line with respect to the feeder. Other standard configurations include a right angle mount and 180 degree angle mounts are available. Multifeeder has created many other configurations to meet specific customer needs. Multifeeder Technology® is an engineering company, and given an opportunity, we will create a solution to meet your needs. The Automatic Product Loader can be positioned in a standard configuration in line with respect to the feeder. Other standard configurations include a right angle mount and 180 degree angle mounts are available. Multifeeder has created many other configurations to meet specific customer needs. Multifeeder Technology® is an engineering company, and given an opportunity, we will create a solution to meet your needs.

A right angle APL configuration.

|

|