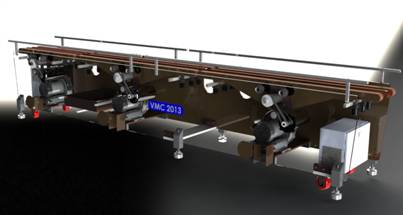

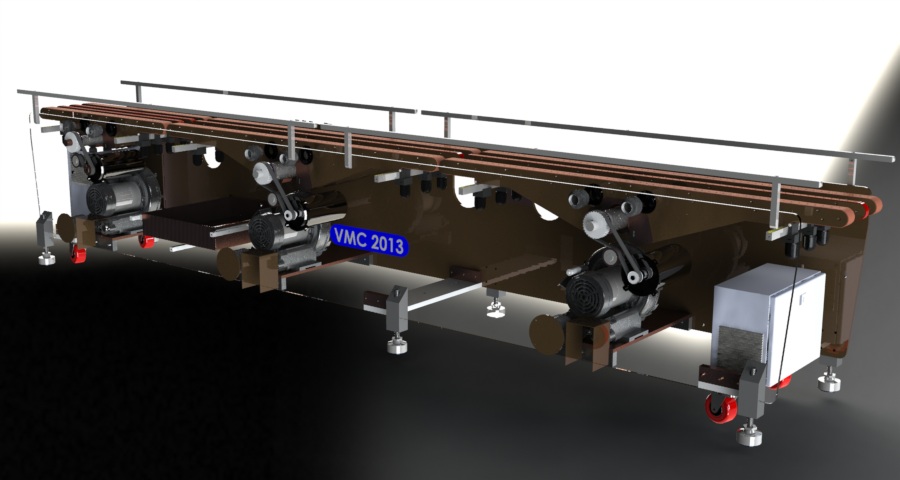

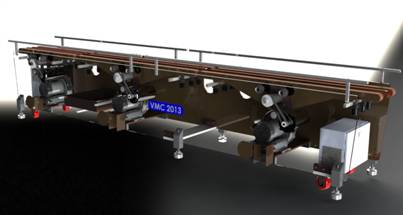

VMC 208

Product Capacity:

Width: 1-20+” (Speeds +450’ minute)

VMC 208 vacuum transport/finishing conveyor - Quality without compromise - from the innovative vacuum system to the anodized aluminum frames. Perform quick, easy, tool-less setups - Plow folding, scanning, ink jetting or placement. This system is our premier conveyance line with all the length and versatility needed for multiple finishing processes. VMC 208 provides outstanding performance and operator versatility.

Attributes:

Attributes:

- Advanced technology vacuum system

- 1/2” Anodized aluminum frames

- Handwheel for each section

- Adjustable height (6”)

- Rubber coated vacuum conveyor belts

- Interchangeable 1 & 2” drives

- (2) 5’ / (1) 3’ VMC sections

- Independent vacuum controls

- All tool-less adjustments

- Cantilevered infeed and discharge

- Adjustment scales

- Built in / sealed encoder location

Easy access external vacuum filters

Easy access external vacuum filters

Vacuum system is engineered for application

- Adjustable

- Self-modulating

- Quiet

- Powerful

- Stall-resistant

- Efficient

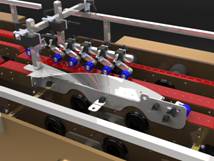

Optional Add-On Components:

QC – Up-Divert

|

Flip Plate (Tipper Plate)

|

Plow Folding

|

Compare to others:

- Tool-less design – No tools needed to perform most set-ups/changeovers.

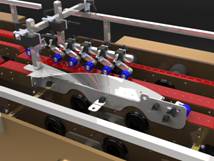

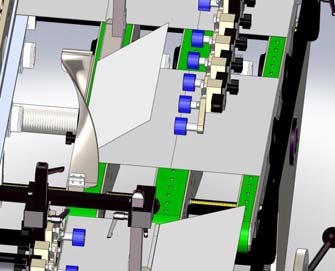

- Vacuum belt construction is of a slippery backer with a 35D rubber cover, perforated for vacuum assistance – The slippery backer provides an extremely low coefficient of friction (belt to fixed surface).

- Each chamber (18”/30”) of tube is vacuum regulated (2 sectors per tube) this vacuum system is engineered for consistent, even pull-down - “loaded” or “open” - Stall resistant design.

- Component design – All pivot points have bearings - expense not a factor in assembly – all components designed to last.

- No tab/air blasters - Linemods utilizes air assisted mechanical ramping assemblies that are easy to set-up, quiet and use a fraction of the air – Ties into existing glue system controller or Linemods multifunction PLC.

- 2-year warranty – We are confident with our parts/equipment designs and back them with a 2 yr warranty.

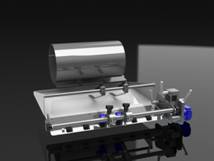

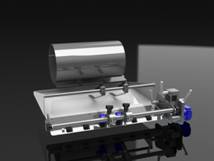

Vacuum System Details:

Large 1-1/2” ID bellows assures uniform vacuum throughout vacuum tubes - If you have had a feel of other vacuum conveyors, you will quickly realize this feature truly makes your set-ups simple – When you adjust your tubes side to side the bellows extends or retracts to fit the exact length – no sagging hoses…

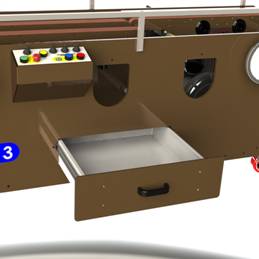

Operator controls are simple to understand and are premium quality ABB components –Quality in/Performance out. All 20”+ VMC vacuum conveyors utilize operator adjustable vacuum modulation system(s).

All VMC units are performance engineered to deliver an optimum supply of vacuum without stalling conveyor or stressing pump – We use regenerative vane vacuum system with pressure sensors that precisely control the vacuum pressure - All tuned from the operator panel – Linemods vacuum systems are designed for the application - unlike many others where blowers are used for a generic vacuum source - This is the most innovative, high performance conveyor vacuum system available.

All VMC units are performance engineered to deliver an optimum supply of vacuum without stalling conveyor or stressing pump – We use regenerative vane vacuum system with pressure sensors that precisely control the vacuum pressure - All tuned from the operator panel – Linemods vacuum systems are designed for the application - unlike many others where blowers are used for a generic vacuum source - This is the most innovative, high performance conveyor vacuum system available.

Feature attributes:

- Solid construction

- Simple electrical/drive components

- Vacuum consistency

- Easy access filter

Waste air is discharged down and out - away from machine/product area.

VMC Filter Cartridge:

Easy access filter system keeps foreign materials from entering pump and is accessed in minutes – Helps prevent glue from entering pump body

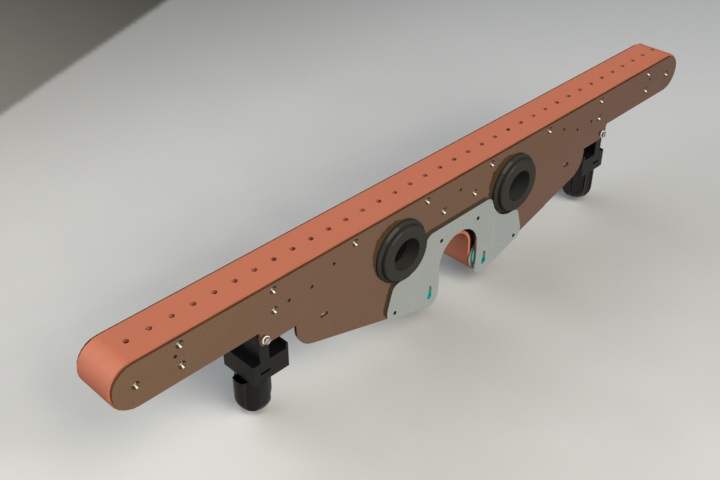

Vacuum Tube Design:

Two tube widths available to handle most any job (1” and 2”) – Linemods VMC tube design promotes easy, tool-less adjustment or quick removal if desired – Belts can be changed in minutes. – Vacuum tubes are split into (2) 18” long chambers – this ensures constant vacuum where you need it the most. Large ball bearing idlers –

Two tube widths available to handle most any job (1” and 2”) – Linemods VMC tube design promotes easy, tool-less adjustment or quick removal if desired – Belts can be changed in minutes. – Vacuum tubes are split into (2) 18” long chambers – this ensures constant vacuum where you need it the most. Large ball bearing idlers –

VMC 3’ – 1” & 2” widths

VMC 5’ – 1” & 2” widths

Handwheel:

Assists in fast, precise set-ups – Easily jogs belts either direction

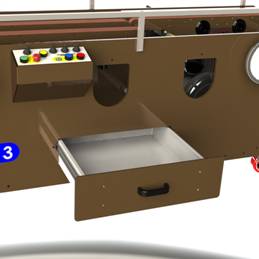

Storage Tray:

Large storage tray to keep tools and loose components

ID measures 19.5” x 21.375” x 4”

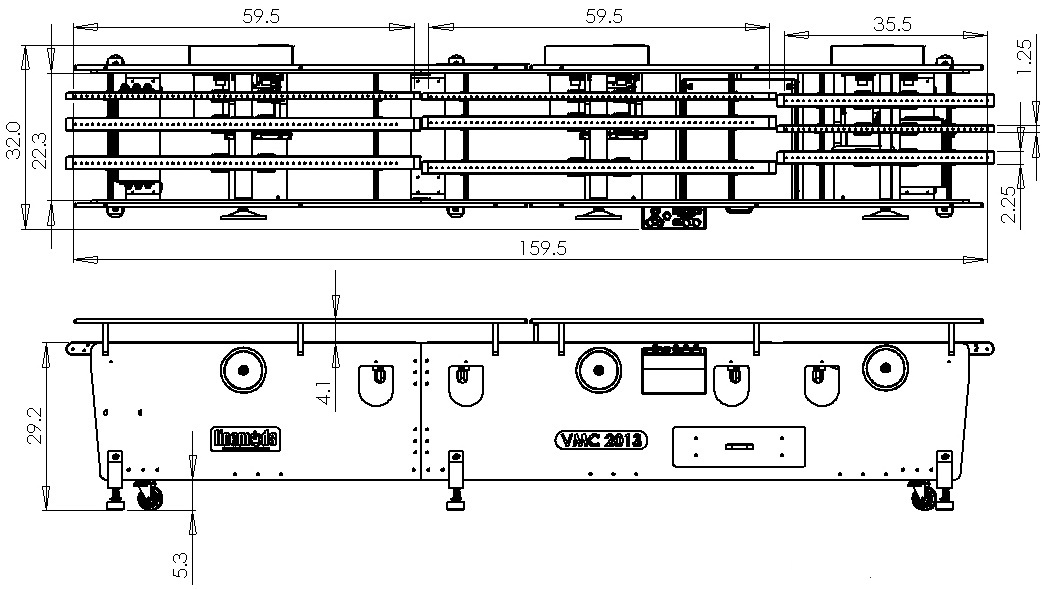

Leveling/Caster System:

Heavy duty vibration isolating leveling system / hard durometer, large diameter casters provide excellent machine portability.

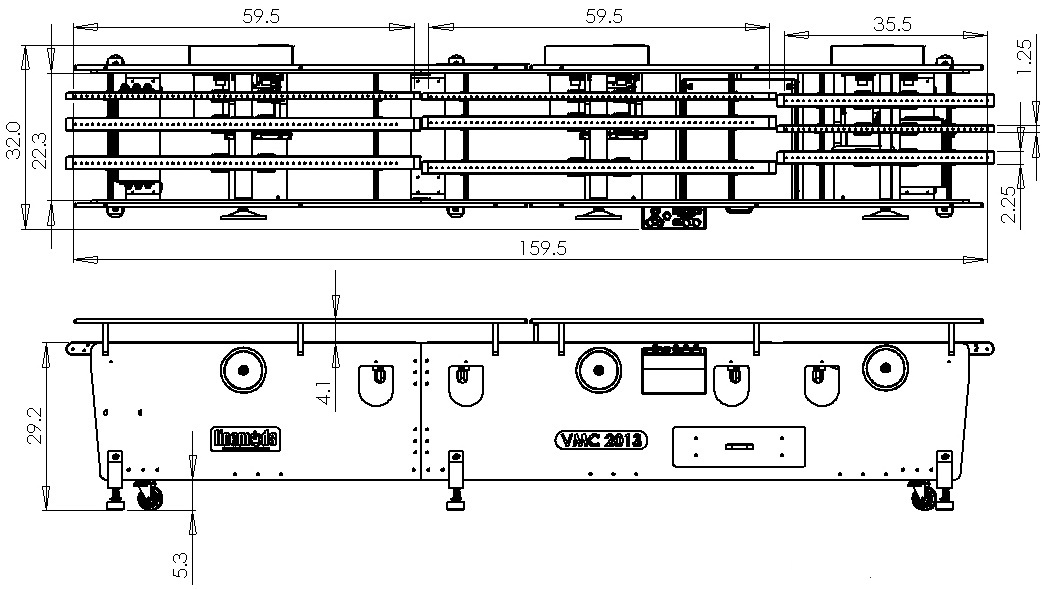

General Machine Specs:

L: 159”

W: 32”

H: 29-35” (Floor to deck)

Weight: 1450 Lbs.

Power: 230V Single Phase (15 amps) |

|

|

|

|

Attributes:

Attributes: Easy access external vacuum filters

Easy access external vacuum filters

All VMC units are performance engineered to deliver an optimum supply of vacuum without stalling conveyor or stressing pump – We use regenerative vane vacuum system with pressure sensors that precisely control the vacuum pressure - All tuned from the operator panel – Linemods vacuum systems are designed for the application - unlike many others where blowers are used for a generic vacuum source - This is the most innovative, high performance conveyor vacuum system available.

All VMC units are performance engineered to deliver an optimum supply of vacuum without stalling conveyor or stressing pump – We use regenerative vane vacuum system with pressure sensors that precisely control the vacuum pressure - All tuned from the operator panel – Linemods vacuum systems are designed for the application - unlike many others where blowers are used for a generic vacuum source - This is the most innovative, high performance conveyor vacuum system available.

Two tube widths available to handle most any job (1” and 2”) – Linemods VMC tube design promotes easy, tool-less adjustment or quick removal if desired – Belts can be changed in minutes. – Vacuum tubes are split into (2) 18” long chambers – this ensures constant vacuum where you need it the most. Large ball bearing idlers –

Two tube widths available to handle most any job (1” and 2”) – Linemods VMC tube design promotes easy, tool-less adjustment or quick removal if desired – Belts can be changed in minutes. – Vacuum tubes are split into (2) 18” long chambers – this ensures constant vacuum where you need it the most. Large ball bearing idlers –