Product Capacity:

Width: 1-20+” (Speeds +450’ minute)

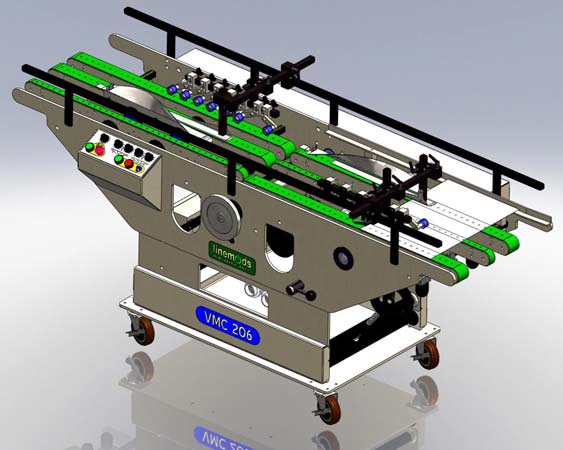

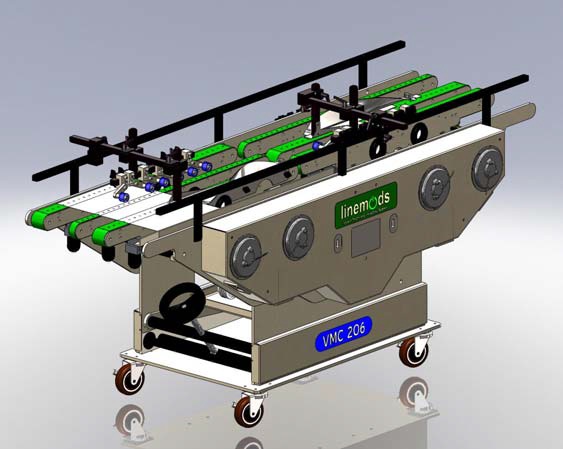

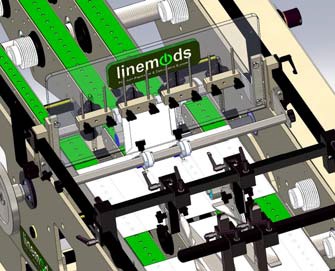

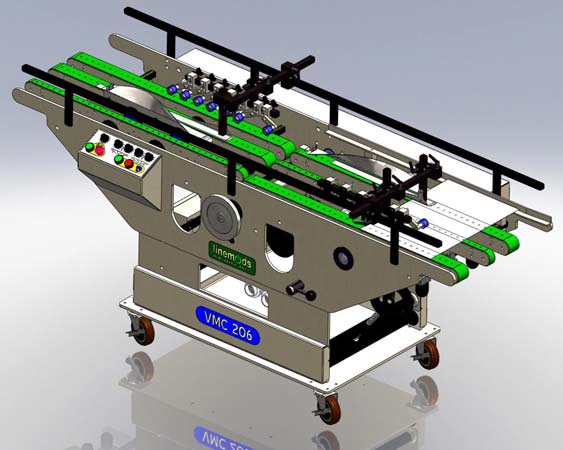

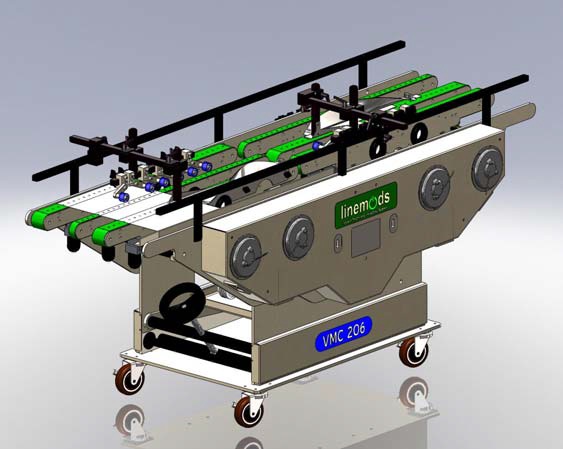

VMC line vacuum transport/finishing conveyors - Quality without compromise - from the innovative vacuum system to the anodized aluminum frames. Perform quick, easy, tool-less setups - Plow folding, scanning, ink jetting or placement. Linemods VMC 203 provides a small footprint and offers features that provide outstanding performance and operator versatility.

Attributes:

Attributes:

- Advanced technology vacuum system

- 1/2” Anodized aluminum frames

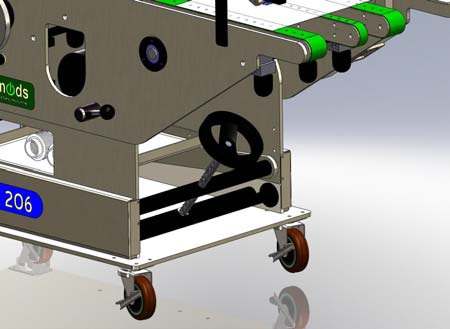

- Handwheel

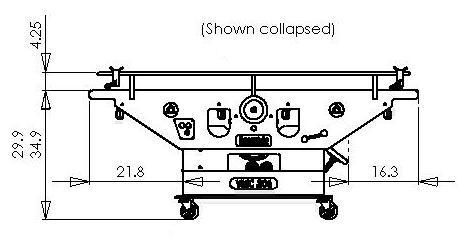

- Adjustable height (6”)

- Rubber coated vacuum conveyor belts

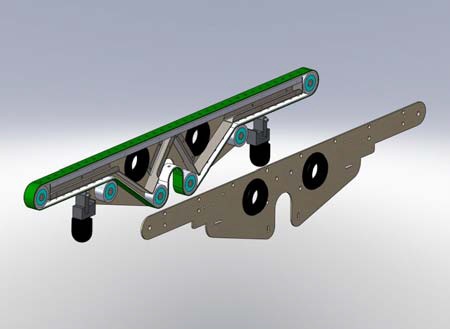

- Interchangeable 1 & 2” drives

- Split vacuum chambers

- All tool-less adjustments

- Cantilevered infeed and discharge

- Adjustment scales

- Built in / sealed encoder location

- Easy access vacuum filter

Vacuum system is engineered for application

Vacuum system is engineered for application

- Adjustable

- Self-modulating

- Quiet

- Powerful

- Stall-resistant

- Efficient

Equipment is designed with a balance of easy operation, longevity and innovation from over 25 years of experience in the post press/production environment – All equipment equipped with a 2-year built-in warranty.

Optional Add-On Components:

QC – Up-Divert

|

Flip Plate (Tipper Plate)

|

Plow Folding

|

Features:

- Tool-less design – No tools needed to perform most set-ups/changeovers

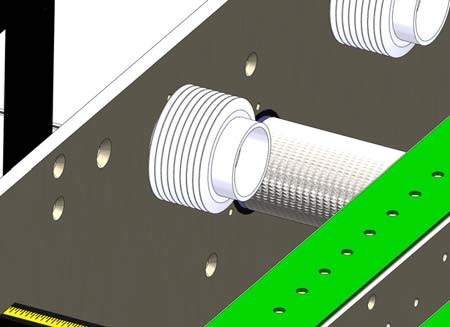

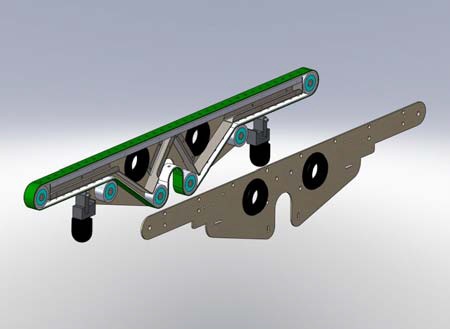

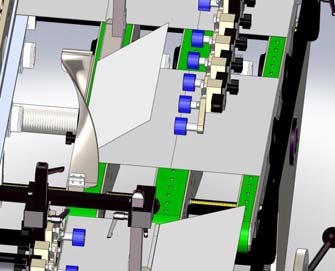

- Vacuum belt construction is of a slippery backer with a 35D rubber cover, perforated for vacuum assistance from deck – The slippery backer provides an extremely low coefficient of friction (belt to fixed surface).

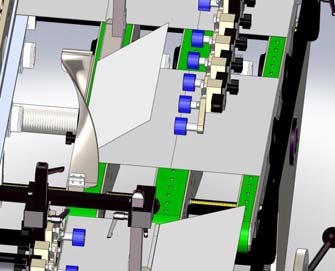

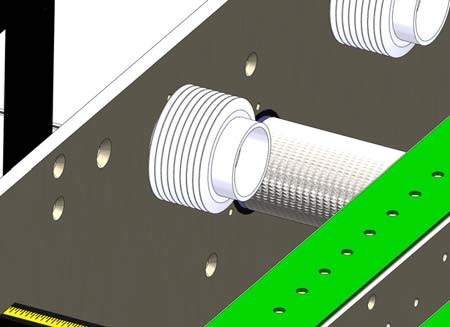

- Each chamber (18”) of tube is vacuum regulated (2 sectors per tube) this vacuum system is engineered for consistent, even pull-down - “loaded” or “open” Stall resistant design.

- Component design – All pivot points have bushings - expense not a factor in assembly – all components designed to last.

- No tab/air blasters - Linemods utilizes air assisted mechanical ramping assemblies that are easy to set-up and use a fraction of the air – Ties into existing glue system controller or Linemods multifunction PLC

- 2-year warranty – We are confident with our parts/equipment designs and back them with a 2 yr. warranty

System Details:

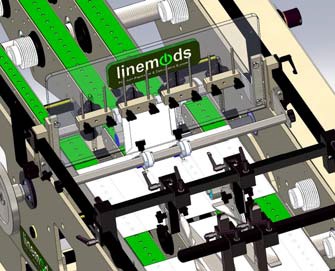

Large 1-1/2” ID bellows assures uniform vacuum throughout vacuum tubes - If you have had a feel of other vacuum conveyors, you will quickly realize this feature truly makes your set-ups simple – When you adjust your tubes side to side the bellows extends or retracts to fit the exact length – no sagging hoses…

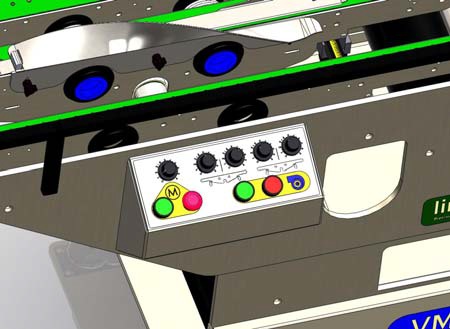

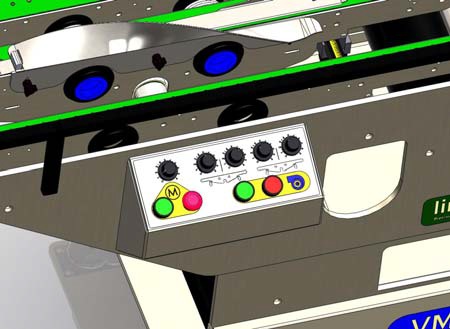

Operator controls are simple to understand and are premium quality ABB components –Quality in/Performance out

All VMC units are performance engineered to deliver an optimum supply of vacuum without stalling conveyor or stressing pump – We use regenerative vane vacuum system with pressure sensors that precisely control the vacuum pressure - All tuned from the operator panel – Linemods vacuum systems are designed for the application - unlike many others where blowers are used for a generic vacuum source - This is the most innovative, high performance conveyor vacuum system available.

Feature attributes:

- Solid construction

- Simple electrical/drive components

- Vacuum consistency

- Easy access filter

VMC Filter Cartridge:

VMC Filter Cartridge:

Filter system keeps foreign materials from entering pump and is accessed in minutes – Helps prevent glue from entering pump body

Vacuum Tube Design:

Two tube widths available to handle most any job (1” and 2”) - Design promotes quick removal if desired or easy adjustment – Belts can be changed in minutes. – Vacuum tubes are split into (2) 18” chambers – this ensures constant vacuum where you need it the most.

We also have 5’ VMC units available.

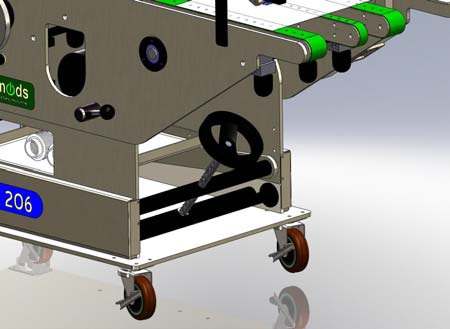

Handwheel:

Assists in fast, precise set-ups – Easily jogs belts either direction

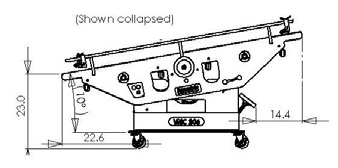

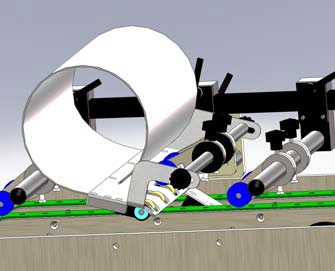

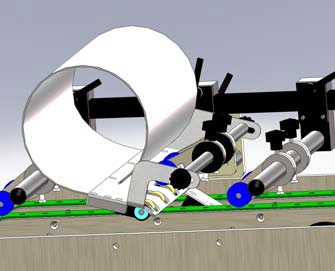

Bed Lift:

Large wheel makes simple height adjustment –

Raise deck up to 5” scissors style lift ensures

stability – this feature assists in roll-up and in-line

converting applications – Again a one man

operation.

Storage Tray:

Large storage tray to keep loose components

Measures 12” x 18.25” with a 1” lip to keep

components contained

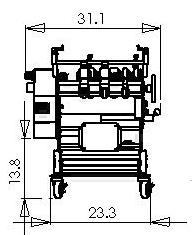

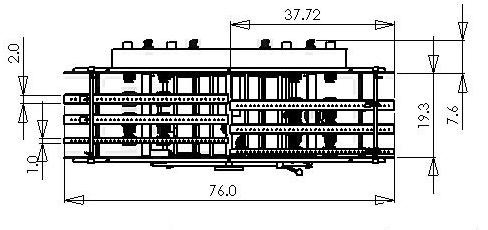

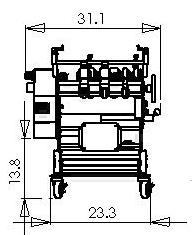

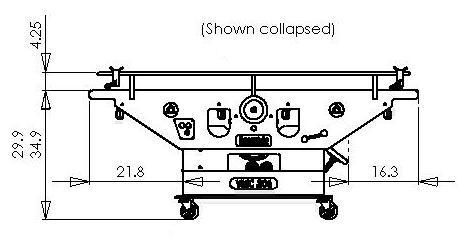

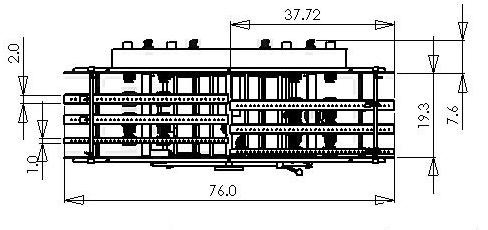

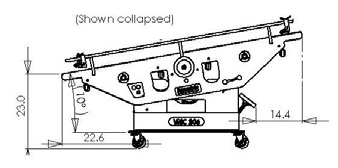

General Machine Spec

L: 76”

W: 31.1”

H: 29.9” (Floor to deck ~ surface collapsed)

Weight: 620 Lbs.

Power: 110/220 Single Phase

(12/6 amp)

Air: 16 cfm @ 80 PSI (Vac

turbo units)

Attributes:

Attributes: Vacuum system is engineered for application

Vacuum system is engineered for application

VMC Filter Cartridge:

VMC Filter Cartridge: