|

|

|

|

|

|

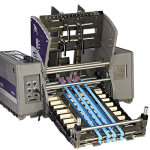

Reliant 1500 |

||

|

||

| V1000 / V1400 / V2000 | ||

|

||

|

|

|

MFT250IP |

MFT 350IP The MFT 950IP handles product varying in thickness from .002" (0.05mm) to 1" (26mm). The product length and width range is 1"x1.5" (26mm x 38mm) and up to 12" wide. The MFT 950IP also singulates a stack of product, so that each item can be coded, labeled, or have a code scanned as it is advanced. |

MFT 550IP The MFT 550IP handles product varying in thickness from .002" (0.05mm) to 1" (26mm). The product length and width range is 1"x1.5" (26mm x 38mm) and up to 20" wide. The MFT 550IP also singulates a stack of product, so that each item can be coded, labeled, or have a code scanned as it is advanced. |

|

|

|

|

| MFT 950IP The MFT 950IP handles product varying in thickness from .002" (0.05mm) to 1" (26mm). The product length and width range is 1"x1.5" (26mm x 38mm) and up to 34" wide. The MFT 950IP also singulates a stack of product, so that each item can be coded, labeled, or have a code scanned as it is advanced. |

The accuracy of a web-tipping application will no longer be measured in fractions of an inch, but in fractions of a millimeter. The 1300DHSL is built with the same durable technology as our high performance friction feeders. Combining proven software with a powerful, robust 800 watt servo-motor, and using a zerØ backlash spider coupling, the 1300DHSL effortlessly applies tip-on product to a web at production speeds while providing years of reliable operation. This system can easily be integrated into an existing production line or as part of a complete solution using one of our versatile accessories such as the Vacuum Track Conveyor or Automatic Product Loader. |

|

|

|

|

|

High Continuous Performance Series expands on the performance and accuracy already built into the Multifeeder Industrial Performance Series Friction Feeders. Available as an MFT 250hcp and 350hcp, it unifies high performance parts with specially tuned software allow you to take your production to the next level of productivity. High linear speeds and tighter placement equate to more product throughput. Contact one of our application engineers to find out how can help you increase your productivity. |

Wash Down Feeder Adding to the versatility and capability of its friction feeder line, Multifeeder created the 350ip Washdown Friction Feeder for food-grade processes. This series consists of our high performing Industrial Performance friction feeders made of Type 304 Series Stainless Steel, the material of choice for food-grade applications. Made with food-grade belts and grease, this series of friction feeders are compatible with FDA standards. |

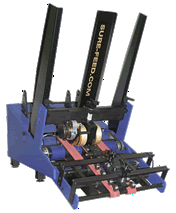

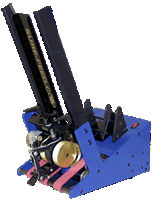

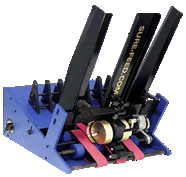

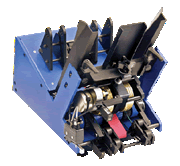

V Series Feeder These cost effective feeders exemplify durability and ease of use. Two different discharge lengths are available including ED and XED. Our Signature Series friction feeders are powered by an 800 watt brushless servo motor which is one of the largest in the industry. This makes our feeders strong enough for the most demanding application, with the reliability to provide years of uninterrupted production. |

|

|

|

The VF200 offers a radically innovative design not available anywhere else. Every part in this feeder - from the precision machined guides, to the sealed shaft locking collar bearings - was designed to take an outstanding amount of abuse. Over 50 inches of two (2) 2-1/2 inch wide belts offer an astonishing amount of friction. Add vacuum to the equation and you have a machine capable of pulling any product. Like all Walco Systems products, the Evolution series feeders are designed for the high capacity use demanded by today's commercial environment. |

Employing every concept that makes up the VF200, the VF400 ups the ante and allows for wider pieces to be fed. Designed primarily for cardboard, this machine allows products to contact 180 square inches of natural gum rubber belting. | |

VF200Material Size: Min. 3"W x 5"L - Max 19.5"W x 28"L Material Thickness: 1" Max (In Standard Configuration) Electrical: 110 VAC 1-Phase 10 Amp Circuit Interlock: Dry Contact (Low Volt) Standard Operator Controls: Power (on/off), Vacuum (on/off), Stop, Jog, Start, Feed Speed Physical: 24"L x 23.5"W x 33-36" H |

VF400Material Size: Min. 3"W x 5"L - Max 41"W x 28"L

Material Thickness: 1" Max (In Standard Configuration) Electrical: 110 VAC 1-Phase 5 Amp Circuit Interlock: Dry Contact (Low Volt) Standard Operator Controls: Power (on/off), Vacuum (on/off), Stop, Jog, Start, Feed Speed Physical: 24"L x 50.5"W x 33-36" H |

|

|

||