|

|

-

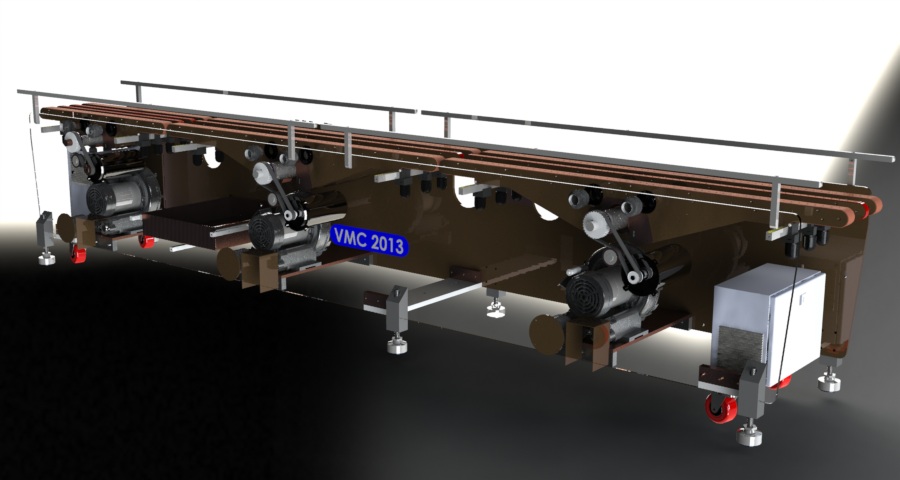

Quality without compromise - from the innovative vacuum system to the anodized aluminum frames. Perform quick, easy, tool-less setups - Plow folding, scanning, ink jetting or placement. This system is our premier conveyance line with all the length and versatility needed for multiple finishing processes. VMC 208 provides outstanding performance and operator versatility.

-

• Advanced technology vacuum system • 1/2” Anodized aluminum frames • Handwheel for each section • Adjustable height (6”) • Rubber coated vacuum conveyor belts • Interchangeable 1 & 2” drives • (2) 5’ / (1) 3’ VMC sections • Independent vacuum controls • All tool-less adjustments • Cantilevered infeed and discharge • Adjustment scales • Built in / sealed encoder location • Easy access external vacuum filters

-

All VMC units are performance engineered to deliver an optimum supply of vacuum without stalling conveyor or stressing pump – We use regenerative vane vacuum system with pressure sensors that precisely control the vacuum pressure - All tuned from the operator panel – Linemods vacuum systems are designed for the application - unlike many others where blowers are used for a generic vacuum source - This is the most innovative, high performance conveyor vacuum system available.

-

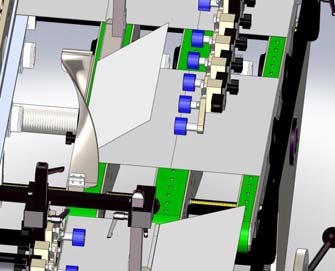

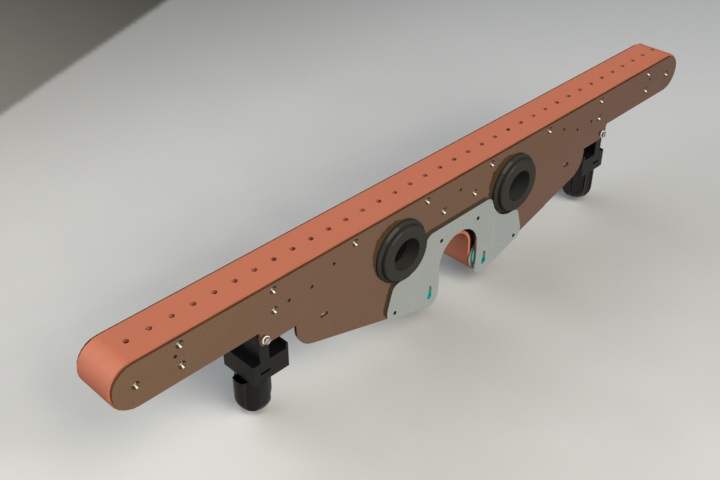

Two tube widths available to handle most any job (1” and 2”) – Linemods VMC tube design promotes easy, tool-less adjustment or quick removal if desired – Belts can be changed in minutes. – Vacuum tubes are split into (2) 18” long chambers – this ensures constant vacuum where you need it the most. Large ball bearing idlers – VMC 3’ – 1” & 2” widths VMC 5’ – 1” & 2” widths

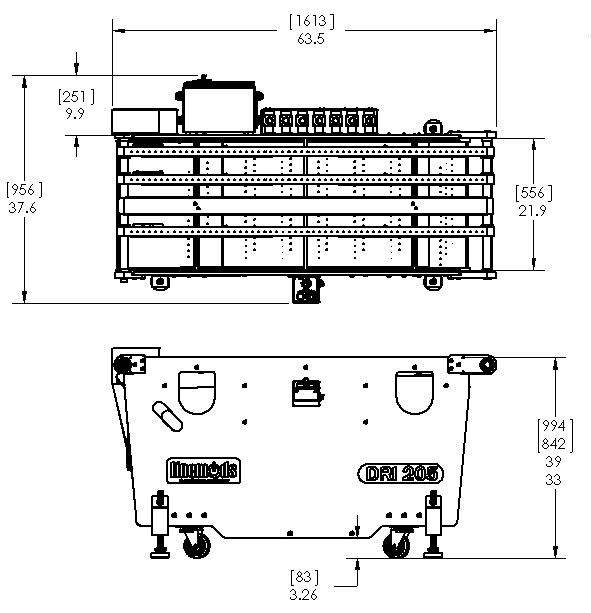

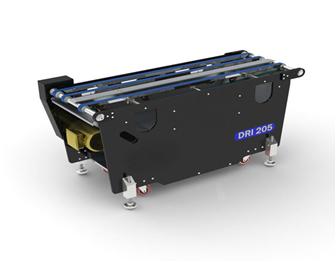

DRI 205

Product Capacity:

Length: 2”+ / Width: 1-20”+ / Speed: +550’ minute

VBC Configuration: (5’)

Dryer base (DRI) vacuum transports/finishing conveyors – Dramatically increase your productivity with

our equipment - Quality without compromise, from the innovative vacuum system to the powder coated “solid”

aluminum frames. Perform quick, easy, tool-less setups with the highest quality deck components available –

Designed from the ground up to cover the most demanding of environments. –“Shake-free” quality (made in the

US)

Model 700-831 Shown

Attributes:

Advanced technology vacuum system

Premium VFD Vector Drive (3/4 HP)

Bi-directional

1/2” Powder coated aluminum frames

Adjustable height (6”)

Premium silicone conveyor belts

2.5 HP of Vacuum

Tool-less adjustments

Cantilevered infeed/discharge

Efficient

Expandable

|

Adjustment scales

Simple maintenance

Built in/sealed encoder location

Easy access vacuum filter

Storage drawer

Power-Vented reflector system

Self-modulating

Quiet

Powerful

Stall-resistant

|

Equipment is designed with a balance of easy operation, longevity and innovation from over 25 years of experience in the post press/production environment – All equipment equipped with a 2-year built-in warranty.

|

|

| |

|

|

|  |

|

| |

|

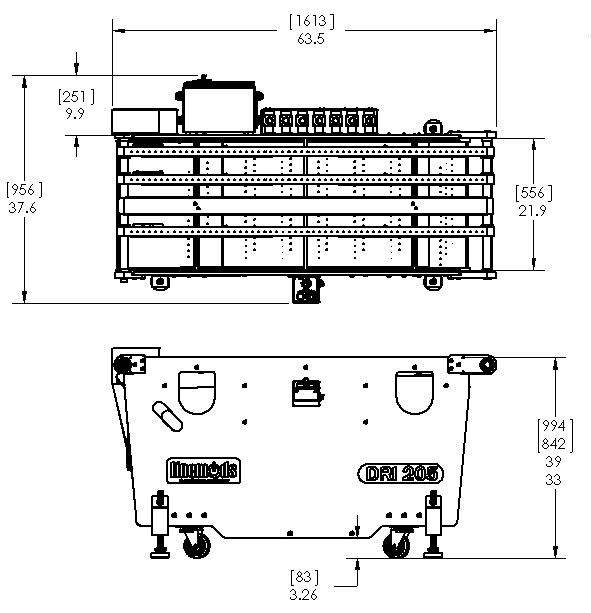

| General Machine Specs:

L: 63.5”

W: 37.6”

H: 33-39” (Floor to deck)

Weight: 475 Lbs.

Power: 230V Single Phase (20 amps)

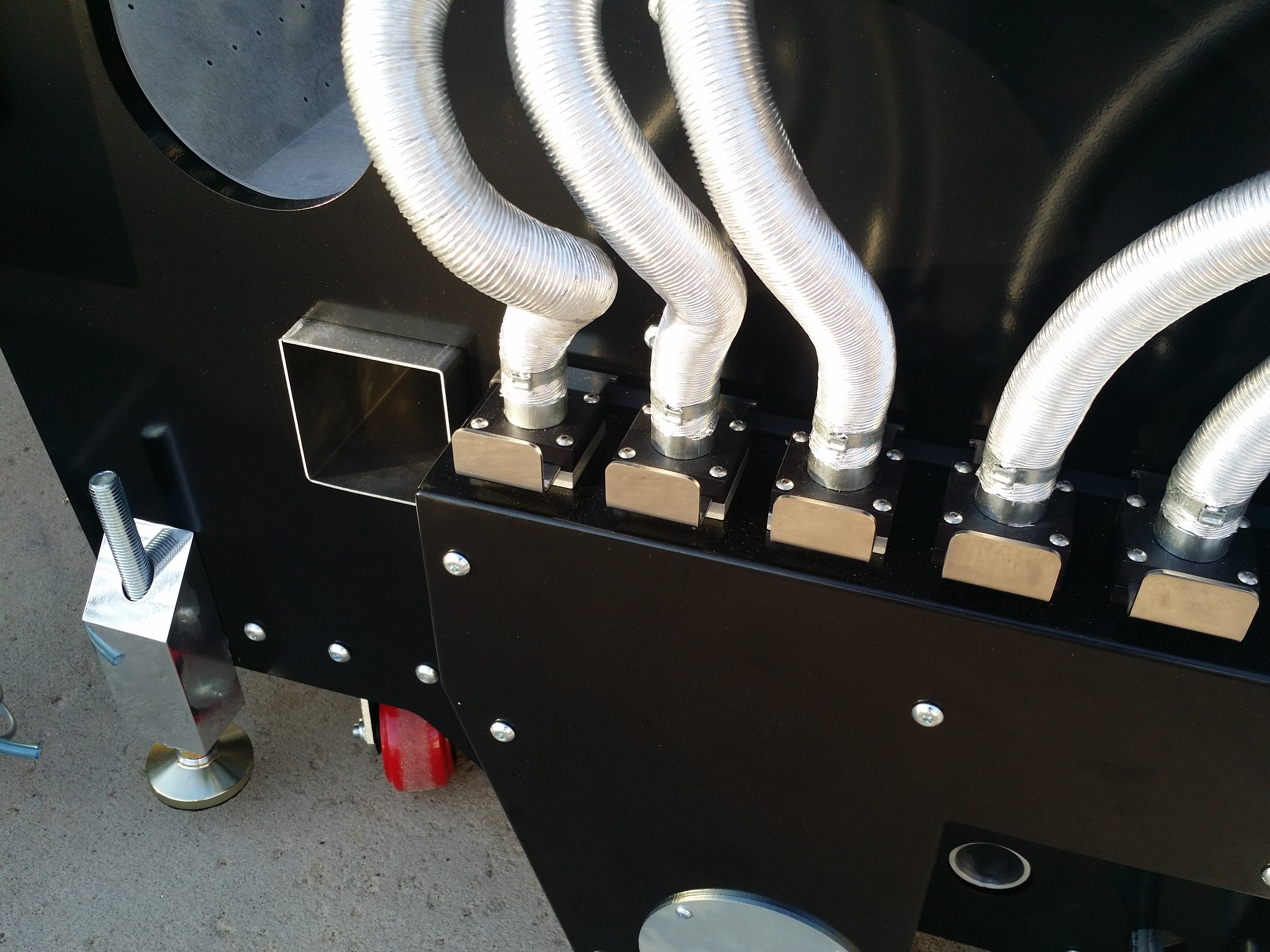

5’ VBC section contains:

(3) 1.5” x 5’ VBC Transport

(1) Fixed sheet support

(6) Super high temp hoses/valves

(1) 2.5HP Vacuum Pump |

|